Diesel engine pumps are a vital type of machine used to transfer fuel from one location to another. Instead, there are little pieces working together, functioning like a team, to make sure the pump performs properly. These pumps play a crucial role in many industry sectors, such as agriculture, mining, construction, and transportation. They are known to be strong, powerful, and efficient; so they can do their work and not waste energy.

How Diesel Engine Pumps Work Using The Combustion Process This is the way they transform fuel to energy. The fuel (typically diesel) enters the engine and mixes with air. And then a tiny spark ignites the airplane fuel/air mix in the cylinder, causing a small explosion. That blast generates a ton of pressure, and that pressure forces a part known as a piston. Next, the piston moves and spins another piece named a crankshaft. This crankshaft is attached to a shaft, which is connected to the pump itself. All of this action is moving the fuel from one place to another, so everything runs like clockwork.

Type of FuelDifferent pumps are designed for different fuel types, so it’s very important to select a pump that is right for the fuel you’ll be using. That allows the pump to operate more efficiently over time.

Fuel Flow Rate: Your pump must have the appropriate fuel flow rate. The downside of picking a pump that isn’t big enough for how much fuel you have to move can cause problems. Always check the flow rate of the pump to ensure it is up to the job.

Job Type – Consider what kind of “work” the pump will be doing. Some pumps are made to do heavy jobs that need a lot of power while others are designed for lighter work that doesn’t require as much strength. Selecting the proper pump for the project will ensure everything goes smoothly.

Today at the highest efficiency: These pumps are very efficient; this means that they can move a lot more fuel while using less energy. That will save you money in the long run.

There Are Less Harmful Emissions: They are even more environmentally friendly, yes, they produce lesser harmful emissions than that of gasoline engines. That means they contribute to cleaner air.

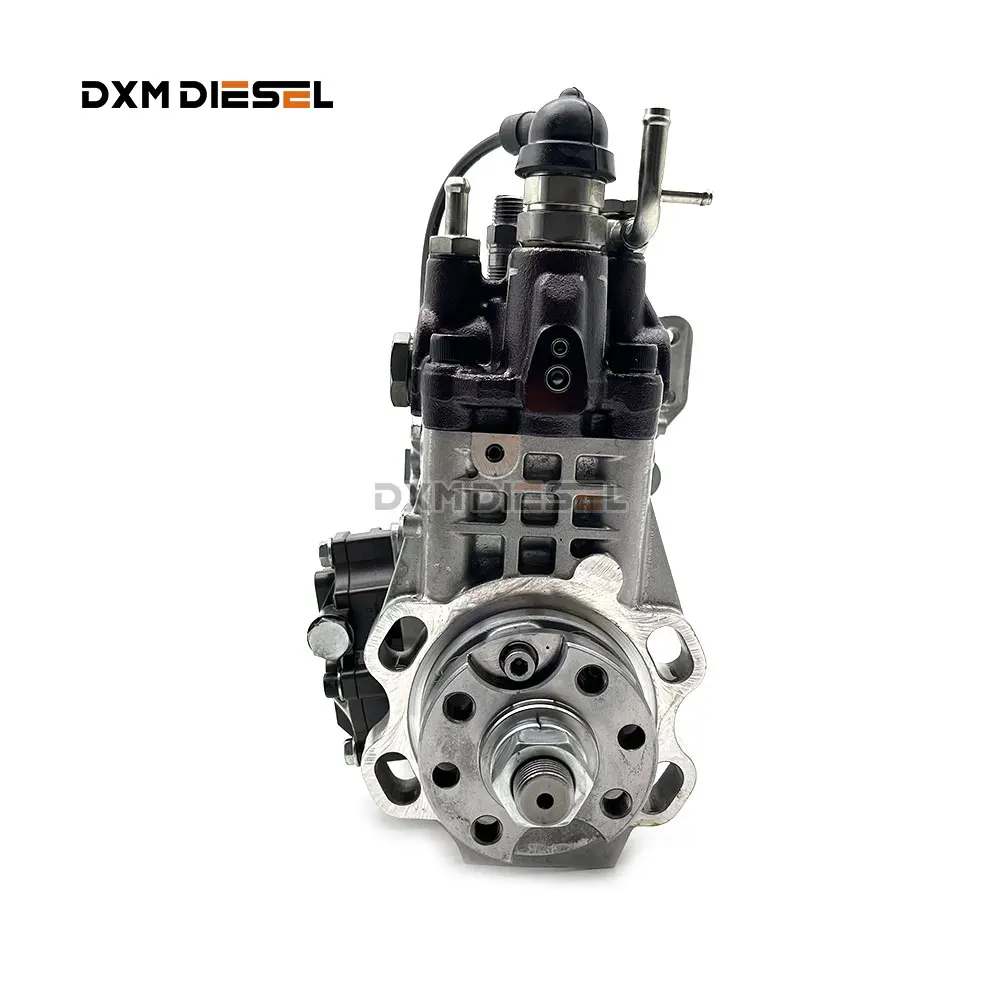

DXM DIESEL has precision production equipment such as BOSCH and Hardridge to ensure high precision and high efficiency in the product manufacturing process, thereby ensuring the stability and reliability of product quality.

Since its establishment in 2007, the company has focused on the field of diesel injection systems and has accumulated 13 years of production experience. It can deeply understand customer needs and provide professional technical support and services.

DXM DIESEL is equipped with strict testing equipment to ensure that each product undergoes comprehensive performance testing before leaving the factory to ensure the reliability and durability of the product in actual application.

The company adopts standardized production processes and has passed SGS certification to ensure that every production link meets international standards and further improves product quality and consistency.