Most machines we work with daily have essential diesel fuel systems. These machine types are tractors, trucks and generators. Fuel injector pressure testers are specialized testing devices used to ensure that the fuel is directed towards the engine in an optimal manner. They assist in making sure the fuel is delivered accurately and efficiently which is critical for machine operation. A test pump injector is an equipment used to test the pressure and fuel delivery rate to the engine.

If you need the easiest way to use a testing pump fiducial, you can just simply follow these steps. Below are the steps you need to follow.1. Connect the gauge to test pump injector So the gauge helps see the readings. Then you will attach the test pump injector to the fuel line, which is the point through which the fuel flows. Then the handle needs to be pressed to activate the test pump injector. This will put pressure and initiate the testing process. Next, carefully read the gauge to confirm both the pressure and flow rate are appropriate or in the safe zone. Finally, if the readings are incorrect, you can adjust the fuel system to ensure that everything is operating correctly.

Tractors and other types of equipment use diesel fuel systems to operate in farming. The most common problem people may have is getting inaccurate readings with their test pump injectors. If the pressure/flow rate readings fall out of range, there is a problem up in the test pump injector or in the system. The second problem farmers may face is leaking fuel system. A leak can affect the pressure and flow rate and give incorrectReadings by the test pump injector. To avoid any disturbances in the flow of work, these issues should be checked regularly.

Diesel fuel systems are also required to operate marine engines, using boats and ships. A high-quality injector test pump is extremely useful. It helps by ensuring that the fuel delivery system is functioning properly, which can make the engine last longer and make it work better with fuel. Test pump injectors give accurate readings, which help ensure everything is working properly. The injectors are also engineered to withstand harsh oceanic or large body of water environments.

And digital gauges are the latest incarnation of test pump injectors that provide even more precise measurements. Ones such as these digital gauges show numbers with clarity and ease of use. Not to mention, for testing from aforementioned remote tests, there are new injectors for a pump which makes the test far easier. Fifth, advancements in technology have made the testing of diesel fuel systems much easier and more efficient. These new tools will give you result faster and make sure everything is working properly.

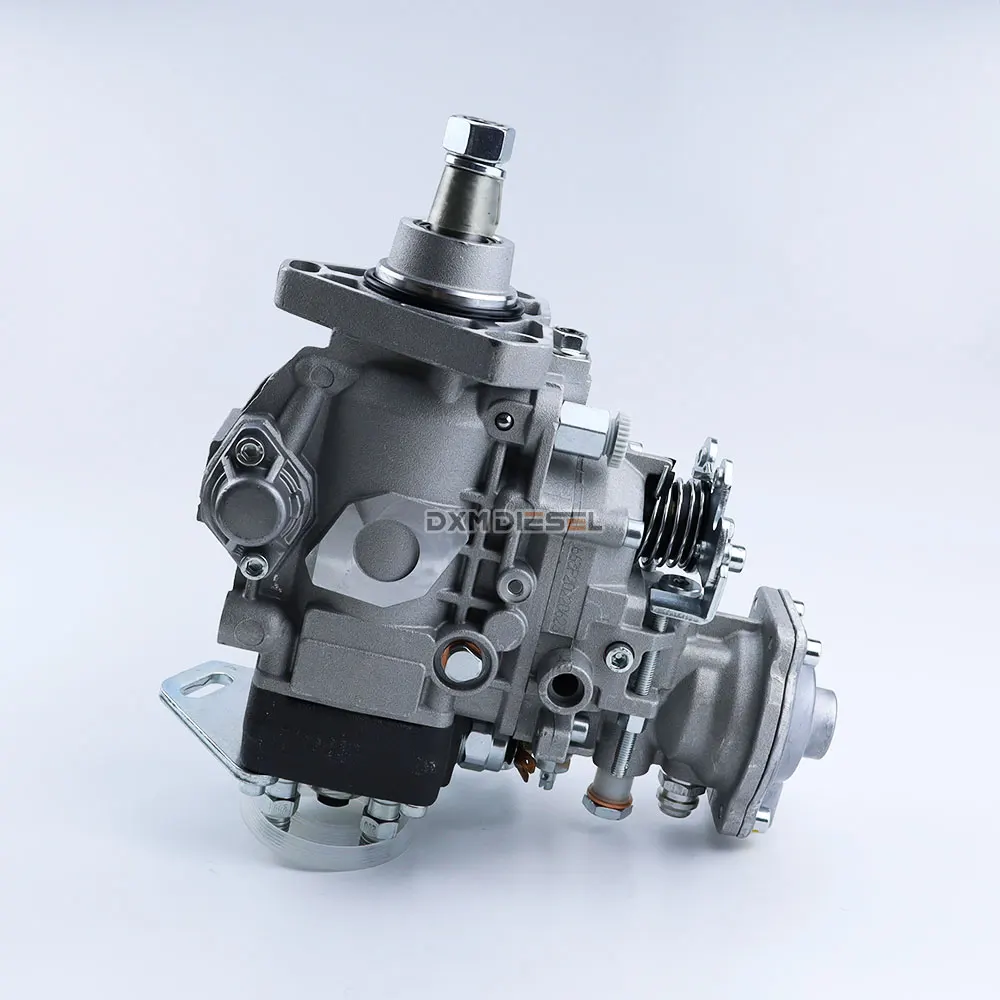

DXM DIESEL has precision production equipment such as BOSCH and Hardridge to ensure high precision and high efficiency in the product manufacturing process, thereby ensuring the stability and reliability of product quality.

The company adopts standardized production processes and has passed SGS certification to ensure that every production link meets international standards and further improves product quality and consistency.

DXM DIESEL is equipped with strict testing equipment to ensure that each product undergoes comprehensive performance testing before leaving the factory to ensure the reliability and durability of the product in actual application.

Since its establishment in 2007, the company has focused on the field of diesel injection systems and has accumulated 13 years of production experience. It can deeply understand customer needs and provide professional technical support and services.