If you have been in a car or seen one on the road, you have most likely heard of something known as the fuel injection pump. But what is this system, and why is it critical for vehicles? It is a very important component of a vehicle's engine alongside the injection system It assists in regulating the amount of fuel pumped into the engine and how that fuel is used to drive the car. This system operates sending a precise amount of fuel into the engine's cylinders at the right moment. This assists the vehicle in operating optimally, quietly, and effective, resulting in better overall performance with less waste.

This is how carburetors in pistons engines work, but in the olden days car engines used a device called a carburetor to mix fuel and air together before it reach the engine. However, now most engines use a fuel fuel injection system instead. This transformation has proved helpful for a plethora of reasons. The key advantage of fuel injection systems is that they can more precisely control the amount of fuel that makes it into the engine than carburetors. This means that the engine can perform better and consume less fuel. Additionally, the smooth operation of the engine aids the overall driving experience thanks to the fuel injection systems. In fact, they could even make the engine longevity longer over time, saving money you would spend on repairs and replacements.

We have two other types of injection systems that we will discuss about. The direct injection is the first type. The system injects the fuel directly into the cylinders in the engine, which allows for a more complete, efficient burn of the fuel. The second type is known as port injection. With this system, fuel is injected into the engine's intake manifold before being drawn into the cylinders. Every variety of injection system carries its own pros and cons. Direct injection systems, for instance, are often more powerful and more fuel efficient, but they can also be expensive and challenging to maintain. Conversely, port injection systems are often less complex and more reliable but may not achieve the same performance that direct injection systems can provide. Knowing that these distinctions exist can aid you in making better decisions regarding cars.

As with any other component of your car engine, unless you want your injection system to function at the maximum of its ability, you need to take care of it. Preventative maintenance can help avoid issues. For example, system cleaning should prevent dirt and debris from clogging it up, leading to problems over time. Furthermore, not to forget that you should also use the proper type of fuel for your car and the injection system in order to maintain the injection system in a healthy condition. Always check your owner’s manual or consult with a professional about the best fuel for your car.

Despite the advantages of the injection system, it can still be problematic from time to time. Common problems can include clogged fuel filters, broken fuel lines, and malfunctioning fuel injectors. A bad injection system could also give a few different indications that it is giving up on you, if you notice your car is not performing right, or you feel abnormal noise coming from the engine, it could be a sign that your injection system is faulty. If you suspect there is an issue, it's a good idea to have a mechanic inspect it as soon as possible. These issues may be minor but not addressing them can result in worse running of the engine, unnecessary consumption of fuel, costing you an expensive engine repair later on.

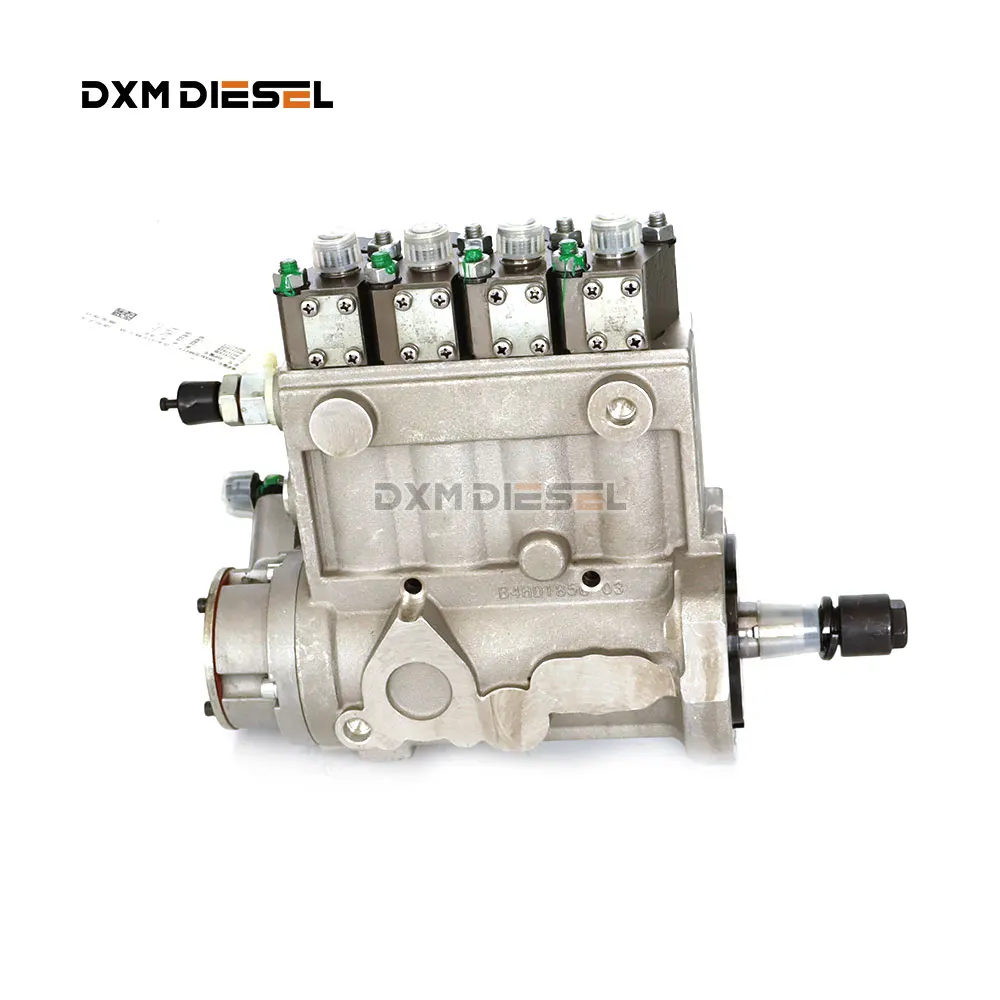

The company adopts standardized production processes and has passed SGS certification to ensure that every production link meets international standards and further improves product quality and consistency.

DXM DIESEL is equipped with strict testing equipment to ensure that each product undergoes comprehensive performance testing before leaving the factory to ensure the reliability and durability of the product in actual application.

DXM DIESEL has precision production equipment such as BOSCH and Hardridge to ensure high precision and high efficiency in the product manufacturing process, thereby ensuring the stability and reliability of product quality.

Since its establishment in 2007, the company has focused on the field of diesel injection systems and has accumulated 13 years of production experience. It can deeply understand customer needs and provide professional technical support and services.